Types of valve tests

Valve tests are done to verify and to ensure that the valves are suitable for factory working Conditions.

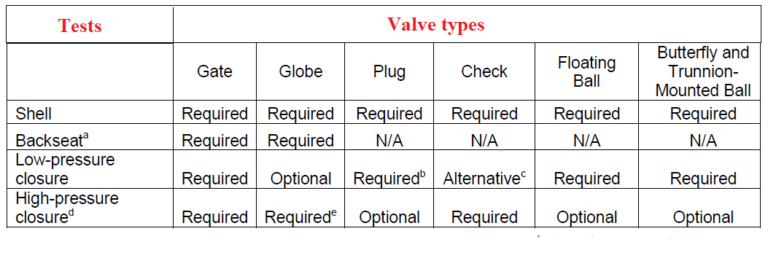

There are different types of tests that are carried out in a valve. Not all the tests should be done in a valve. Types of tests and tests required for valve types are listed in the table shown below:

Test fluid used for shell, backseat and high pressure closure is air, inert gas, kerosene, water or non-corrosive fluid with a viscosity not higher than water. The maximum fluid test temperature is 1250F.

Types of valve tests:

Shell test:

Backseat test

Performed for valve types that have a back seat feature (at the gate and globe valve). Performed by applying pressure on the body valve with the valve condition fully open, both ends of the valve connection closed and the gland barrier packing open, to ensure strength against design pressure and ensure there are no leaks in the seal shaft or closing gasket.

Pressure requirements: performed with a pressure of 1.1 x pressure rating material at 1000F.

Low pressure closure test

Performed by pressing one side of the valve with the valve position closed, the emphasis is carried out with air media and one side of the open connection is faced up and filled with water, the leak will be seen because of the air bubbles coming out.

Pressure requirements:performed with a minimum pressure of 80 Psi.

High pressure closure test

Performed by pressing one side of the valve with the valve position closed, the pressure is carried out with water media and leakage will be seen due to the outflow of water droplets.

Pressure requirements:performed with a pressure of 1.1 x pressure rating material at 1000F